The Description of the NEW XCMG LW700KN Coal wheel loader

Are you still wasting time looking for Wheel loaders suppliers?

Do you still worry about product quality assurance?

Are you late in deciding to buy because of insufficient budget?

If you have these worries, stay and see.

Factory Direct

Fast shipping

Full warranty and spare parts

NEW XCMG LW700KN Coal wheel loader with coal Bucket 6m³, Operating weight 25.5tXCMG LW700KN Coal wheel loader is a new generation of full build wheel loader especially suitable for the working condition of overloading of the K series loader dominant model, in the absorption of the introduction of foreign advanced design and manufacturing technology at the same time, by the broad market and technology research and development and design of a new type of loader. This machine can meet the requirements of high strength and continuous operation, in, comfort, safety, reliability, maintainability, and have significant improve work efficiency, won a good market.

HOT PRICE FOR AFRICA AND THE MIDDLE EAST

Since foundation in March 1943

Since foundation in March 1943, XCMG has always kept its leading role in Chinese and World construction machinery industry.

As one of Top 5 World Manufacturers of excavator, loader, crane, roller, grader etc.

We sell all machinery at the factory selling price.

All machines are in stock and ready for shipment

Minimum quantity 1 machine

Rated operating load 7000 kg

Coal Bucket capacity 6m³

Machine weight kg 25500

Engine: Weichai WD12G310E221

Wheel Tread 2710 mm

Tyre size 26.5R25

Delivery Time: 7-10 days

Supply Ability: 50 units per month

Features of XCMG LW700KN coal Wheel Loader

XCMG LW700KN is a new generation of N series 7-ton loader, designed for the working conditions of light materials such as coal, and its design concept emphasizes economy and practicability.

The 700KN design pays more attention to the psychological expectations of users while meeting various performances, and considers the return period of investment costs from the users point of view.

Therefore, the design is based on the principle of economy and applicability, and it is more beneficial to customers with higher cost performance.

Through re-integration of the product platform, the frame, working device, hydraulic system and power system are optimized and upgraded, and the versatility of the product is guaranteed to the greatest extent to reduce production costs.

High-end configuration:

High-end configuration: Weichai National II engine, supercharged and intercooled, low emission, strong power, superior performance; German ZF box, XCMG super dry bridge, high reliability; three-section drive shaft, smooth transmission; hydraulic pilot The control and operation are light and easy to ensure the reliable operation of the whole machine.

Product features:

Product features: lightweight structural parts, energy saving and consumption reduction.

Standard ZF electronically controlled gearbox from Germany, super heavy-duty, safe and reliable.

The centering design of the main hinge point reduces the turning radius, makes the steering operation more flexible, and reduces tire wear and energy loss.

Sound insulation, shock absorption, and the noise in the cab meets international standards.

The micro-pressurized and dust-proof cab is equipped with audio and air conditioning as standard, providing an excellent working environment for the operator.

he exhaust drainage structure effectively reduces the temperature in the engine room.

Performance specialty:

Performance specialty:

The turning radius is small and the transition operation is more flexible.

The traction force is 220KN, and the work is strong and powerful.

Lightweight structure, energy saving and consumption reduction.

Comfortable operation, safe and reliable.

Excellent quality transmission system

International advanced level ZF4WG260 high-power heavy-duty automatic electro-hydraulic control gearbox

ZF automatic fixed-axis electro-hydraulic control gearbox, with overweight carrying capacity, strong torque transmission capacity, high safety factor, high reliability, and adaptable to various complex and overweight working conditions. Full flow electro-hydraulic control, simple, comfortable and efficient operation.

ZF4WG260 high-power heavy-duty electronically controlled gearbox has powerful functions.

XCMG self-made super drive axle

XCMG self-made super drive axleLightweight design of structural parts

Frame structure with superior load-bearing capacity

Optimized design, thick plate structure, robot welding, strong welding seam, high torsion resistance and strong overload capacity.

The new rear frame structure has high structural strength and strong earthquake resistance.

The use of finite element analysis technology reduces stress concentration and eliminates local weakness. The frame is resistant

to impact and overload, and it is easy to handle in various overweight conditions.

Solid and reliable frame articulation

Solid and reliable frame articulationThe hinged point centering design reduces the turning radius, reduces tire wear and energy loss.

The upper and lower hinged plates have large spacing, excellent structural strength, and sufficient maintenance space.

The main hinge point adopts two sets of tapered roller bearings, which have strong load-bearing capacity and long service life.

High-strength and wear-resistant bucket design

The bucket is fully made of high-strength steel plate, which improves wear resistance and impact resistance by more than 30% and has a longer service life.

The key parts are especially strengthened.

The key parts are especially strengthened.The high baffle structure is adopted to reduce material scattering and ensure the maximum material loading capacity.

Optimize the lubricating oil channel: No more holes are drilled on the pin connecting the boom and the bucket, and the strength and service

life of the pin are more than doubled.

Diversified bucket design: 1. Rock bucket, specifically for challenging hard materials such as rocks, resistant to wear and impact;

Coal bucket, specifically for loose materials such as coal, with large bucket capacity and high efficiency.

Robust and durable: Maximize the service life of each system and component

International quality hydraulic and electrical components

International quality hydraulic and electrical componentsInternational brand hydraulic pumps provide more powerful hydraulic power.

It adopts Italian alpha hydraulic hose, which is heat-resistant, pressure-resistant and has a long life.

The hydraulic system has a high-pressure automatic unloading function, which increases the working efficiency of the whole machine,

reduces the heat of the hydraulic system, and reduces the energy loss of the hydraulic systems high-pressure overflow.

The combined operation traction is further improved, energy saving is better, and operation efficiency is higher.

People-oriented, safe and comfortable: spacious, comfortable and safe driving space

Full view cab

Full view cabA luxurious cab with large space, large space and good visibility, an anti-rolling and falling object cab is optional.

The new digital combination instrument is beautiful and generous; the operating elements and buttons within reach can easily realize various operation actions.

Optional advanced working device handle shift to increase work efficiency.

The high backrest has armrests, headrests, seat belts, multi-angle adjustable seats, and adjustable steering gears to meet

the operating habits and requirements of operators of different body types. Optional luxury airbag shock-absorbing seat.

Standard high-power heating and cooling air-conditioning, MP3 player, FM radio, luxury audio, providing car-level driving enjoyment.

The micro-pressurized and dust-proof cab ensures maximum air quality in the cab.

The shock-absorbing and silent luxury cab is the quietest loader in China.

Convenient maintenance: Provide maximum convenience for maintenance and repair

Convenient maintenance: Provide maximum convenience for maintenance and repairThe new frame structure engine cover, the top-turning large side door, the opening angle is large,

the engine and the radiator are easier to overhaul and maintain.

Oil level inspection, oil adding and lubricating grease filling points are all arranged in easy-to-access places,

and the air filter element and electrical components are easy to inspect and replace.

The system pressure detection port is led out centrally, the centralized fuse box, the operating status of the electrical

system is displayed centrally, and the maintenance is convenient.

Powder metallurgy dust-proof respirator, strong and reliable, easy to maintain.

Optional fully-sealed lubrication-free bushings can be selected, which greatly simplifies the daily maintenance of users.

The innovative use of centralized pressure measurement, centralized oil injection, and centralized waterproofing saves time and effort

in maintenance and improves the convenience of maintenance.

Operating comfort

Operating comfortThe cab system can choose a micro-pressurized cab to improve the dustproofness of the cab. It is also equipped with a high backrest, armrests,

and multi-angle adjustable shock-absorbing seats to provide the driver with a more comfortable operating environment.

The new drivers cab has a large space, three-face-connected windshield, a wide field of vision, and no blind spots in the operation field.

The luxurious four-direction adjustable seat has good shock absorption effect and is not fatigued for long-term operation.

Higher reliability

Higher reliabilityThe steering cylinder is changed from the original snap-key structure to a threaded structure. At the same time, the steering hinge points

are optimized, and the steering ear seats of the front and rear frames are strengthened. The steering capability of the whole machine is further improved,

the safety margin is increased, and the reliability is higher.

The transmission shaft is changed to a three-stage type, which has a wider adaptability and further improved reliability.

Increase the sheath of the tipping cylinder hose to place the falling objects bumped;

Using international brand VDO combination instrument, beautiful, reliable and durable.

The hydraulic pipe line adopts imported parts instead of domestic parts to improve the reliability of wearing parts.

The use of high-precision cold-drawn steel pipes has higher bending performance, and the surface is sprayed with plastic treatment to improve

rust resistance. The steel pipe is changed to butt-joint argon arc welding: welding stress, deformation, cracking tendency, etc. are small;

it is easier to obtain dense, high-quality welded joints, reducing cracking points, and improving reliability.

The full set of hoses and joints are made of Alpha products, and the hoses are changed to a 2-layer product with a pressure resistance of 33MPa,

which reduces the failure points of oil leakage at the hose withholding and improves the reliability of the system.

The sealing ring is replaced by a Taiwanese brand, and the joint adopts a double sealing form of 24 deg cone + sealing ring, which completely solves

the leakage problem of the industry.

Imported LED lights can be selected, with low power, greater brightness and longer working life.

Electrical appliances adopt imported plug-in parts to improve reliability

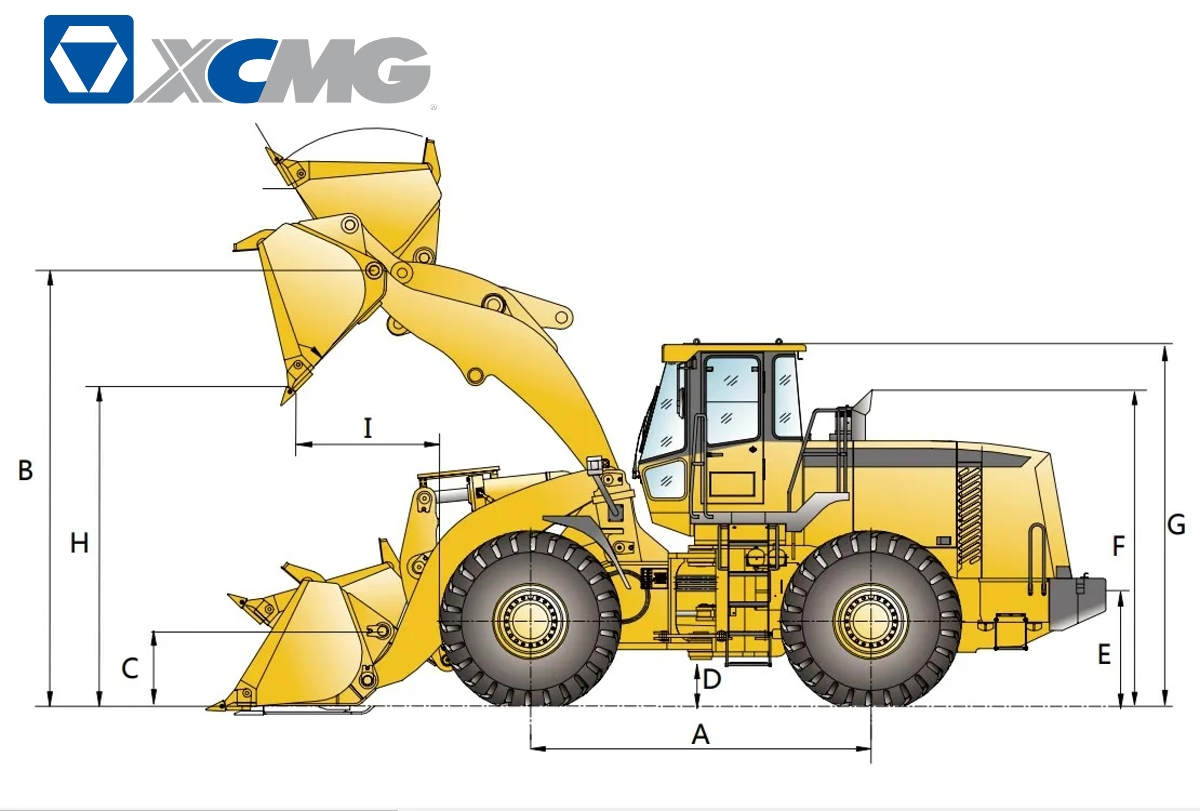

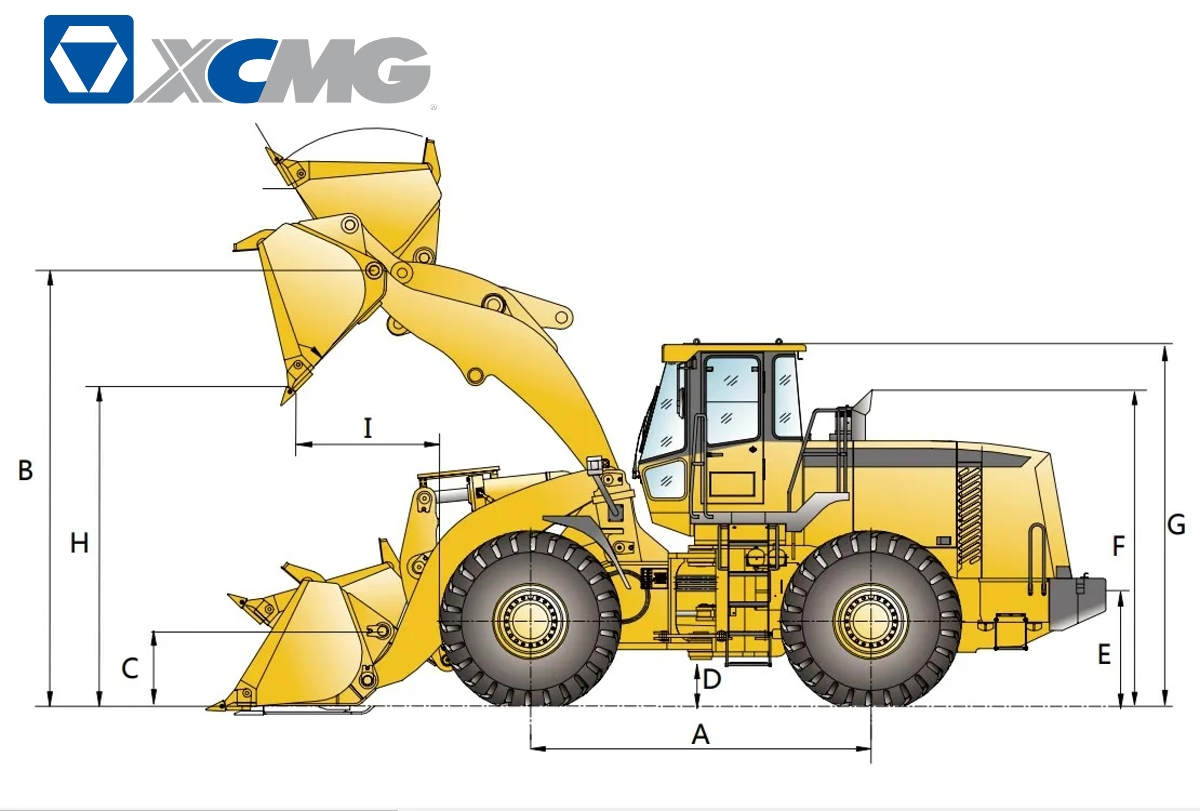

The specification of the XCMG LW700KN Coal wheel loader

Wheel base mm 3450

Tread mm 2360

Dump clearance at maximum lift mm 3515

Reach at maximum lift mm 1388

Height of hinge at maximum lift height mm 4780

Working height(fully lifted) mm 6560

Overall machine dimension LÃ-WÃ-H mm 9455x3430x3630

Rated operating load kg 7000

Bucket capacity m³ 6

Machine weight kg 25500

Max.breakout force kN 150

Max.horse power kN 220

Lifting time of boom s ≤6.5

Total cycle time≤11

Minimum turning radius (at tire center) mm 5920

Articulation angle Â+-40

Gradeability 28 deg

Tyre size 26.5R25

Engine Model Weichai WD12G310E221

Rated Power/Speed kW/rpm 226/2100

Travel Speed km/h 7-38

Engine

Engine

Genuine imported Cummins QSMII engine with electronic fuel injection, turbocharger, intercooler, electric start, electric shut-off.

meets pollution standard Euro & US TIER-III.

B.Gearbox

LW700K adopts original imported ZF-4WG electrical control transmission.It has 4 front and 3 reverse shifts and electrical

control shifting and it has KD function which can improve working and economical efficiency.

It also has protection function of starting at neutral gear.

LW700K has strong ability and can completely meet power request.The settlement of front

4 and rear 3 transmission can improve the using life at the complicated working condition.It has idle protect function

and it can also protect all the components working safely.It has enforceably low shift changing function which can simplify operating

by driver so reducing driver working strength.

Driving axle

The original imported ZF wet axle with limited slip differential and maintenance free wet brake disc increases service

life of the axle.The rear axle center swing reducing the additional torque and load on the impact of the transmission system.

The key block construction machinery transmission has strong shaft impact resistant ability and dynamic transfer characteristics of the high reliability.

Hydrauclic system

Working hydraulic system and power steering system has double pump Confluence of technology which can reduce loss of engine power.

Steering system USES the flow amplifier system and has hydraulic limit device.

The Pilot hydraulic controling system makes operating freely and reduce working strength of driver.

rake system

Full hydraulic wet brake system,low pressure protection,2 in 1 of emergency brake&parking brake make you safe.

Germany Rexroth components improve reliability of the whole system.

Cabin and control system.

LW700K adopts new separated type luxury cabin and it has big operating space, wids phere vision.

Bigger front and rear window make the vision wide.UV colored glass,Silk screen printing sunscreen,sound insulation cabin,warm and cool

air conditioner,luxury seat and reasonable gauges make working comfortable.

Easy to maintain.

All kinds of hydraulic and lubricatioin oil level checking are located easily approaching.Air filter and electronic devides examining

and replacing are really operated.

Frame.

Front and rear frame layout reasonably.Structure is compendious which reduce irregular weldment and enhance affording ability of

torsion and impact load under various working conditions.

Enlarge the distance of articulating pin whch can scatter forces and extend working life.

Adopt DOUBLE-ROW TAPERED ROLLER BEARING at articulating pin which can enlarge bearing force and moving stability.

The rigidity of frame is good.It supply a massy seat for arma dn hydraulic which can absorb srong torque,impact and working force.

Working device and bucket.

Working device by the optimization design, using the single rocker arm, short rod, horizontal movable arm cylinder

type Z inversion of six connecting rod structure, which has excellent operating performance and operating efficiency.

With functions of bucket automatic flat at any position, No need to adjust the state of the bucket shovel when loading again

without adjustment, simplifies the driver operating.

All point of hinge pin shaft lubrication using dustproof structure, which can effectively dust and pollution, protect

the grease from the hinge pin and bushing provides a reliable protection.

Bucket main easy wear parts adopt special wear-resistant plate making, bucket long service life.

Centralized lubrication system (Germany baker)

Centralized lubrication system, which using appropriate pump pressure, timing, quantitative pumping grease to all lubricating points,

guarantee the friction pair to maintain reliable and plenty of oil film, the normal operation of persistent.

Centralized lubrication system mainly includes: for the system to provide the grease and power sources of electric pump, automatic controller

to control the whole lubricating system, limit the system pressure relief valve, a reasonable allocation of grease distributor,

as well as the mandatory switch, piping and connectors, etc.

Automatic controller with a timer, the machine start after start timing, when to set point injection cycle began injecting grease.

If the machine to stop the CPU to save data automatically, starts no longer time again next time, and to the cumulative time,

lest cause insufficient lubrication because of working time is less than the cycle.Injection cycle and filling time can be adjusted on the pump control panel.

Artificial filling grease lubrication system overcomes the intensity of labor is big, and lubricating oil filling quantity,

the shortcomings of time interval is not easy to control.

Reversing image

Advanced reversing visual device for the pilot work has provided a broad rear view vision, has provided reliable assurance for safe operation.

29334 view

29334 view

ADD TO MY CART

ADD TO MY CART

HOT PRICE FOR AFRICA AND THE MIDDLE EAST

HOT PRICE FOR AFRICA AND THE MIDDLE EAST Since foundation in March 1943, XCMG has always kept its leading role in Chinese and World construction machinery industry.

Since foundation in March 1943, XCMG has always kept its leading role in Chinese and World construction machinery industry. We sell all machinery at the factory selling price.

We sell all machinery at the factory selling price.  Rated operating load 7000 kg

Rated operating load 7000 kg Features of XCMG LW700KN coal Wheel Loader

Features of XCMG LW700KN coal Wheel Loader XCMG LW700KN is a new generation of N series 7-ton loader, designed for the working conditions of light materials such as coal, and its design concept emphasizes economy and practicability.

XCMG LW700KN is a new generation of N series 7-ton loader, designed for the working conditions of light materials such as coal, and its design concept emphasizes economy and practicability.  The turning radius is small and the transition operation is more flexible.

The turning radius is small and the transition operation is more flexible.